A world leader in steel production and one of the largest in mining, the ArcelorMittal Group has customers in 160 countries and has more than 190,000 employees. In its 11 research centers, around 1,300 researchers develop more efficient products and processes aimed at generating value for customers and ensuring future growth.

ArcelorMittal Brasil operates in the production of steel in the country, with an installed capacity of over 12.5 million tons/year. With industrial plants in six states, it employs around 16 thousand people. It produces high quality long and flat steel for the automotive, home appliance, packaging, civil construction and shipbuilding industries. It is also active in mining, power generation, production of renewable bioreducer and information technology. Its extensive distribution and service network meets the demands of domestic and international markets.

Through creative environments that relate to the ecosystem, ArcelorMittal encourages and supports the development of innovative ideas aimed at improving the internal processes of products and services, and also aimed at contributing to global efforts to face the global challenges of humanity.

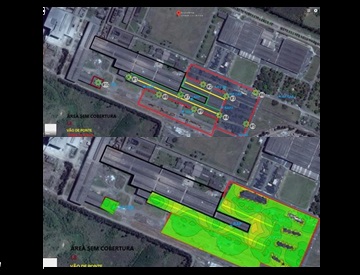

The industrial business unit ArcelorMittal Brasil Longos, based in Juiz de Fora – MG, leads an innovative Industrial Logistics Master Plan program called Intelligent Logistics, comprising a series of projects. This plan was conceived in 2018. In 2019 it was already possible to carry out the first proofs of concept and, even during the entire period of the pandemic (2020/2021) it remained active and strong in its objectives of producing results and delivering the first technological solutions that operate In real time.

In 2021, the project is already showing its fruits, reaching its maturity with the Rollout actions in the Industrial plants. The creator and Project Leader, Wanderson Guedes Terror, Project Specialist & IT and TA Solutions – ArcelorMittal presents the first Technological Innovation packages:

| Technology package | Scope | Description | Solutions |

| TEC1 |  | R&D Research and Development | RFID Tags, RFID Collector, Automation of Forklifts and Overhead Cranes. IT and AT Infrastructure. Application Infrastructure on the shop floor with middleware, MES, SAP. Solutions operating integrated and in real time. Network Infrastructure in the ArcelorMittal Information Security standard and compliance. |

| TEC2 |  | RFID Portal Automatic Collection of Production and Laminated Products | Portal RFID Coletando automaticamente produção de laminados via Portal lendo etiquetas e Tags RFID nos produtos. Aplicações integradas no MES e SAP |

| TEC3 |  | RFID mobile collector | RFID Mobile Collector – Operates with SAP with the functions of moving, auditing, receiving, consulting, shipping laminated products |

| TEC4 |  | RFID Overhead Cranes | Rolling Bridges – Integrated automation solution operating in the movement and dispatch of products |

| TEC5 |  | RFID Forklifts | Forklifts – Integrated automation solution operating in the movement and dispatch of products |

| TEC6 |  | RFID Anti-Fraud Portal | Antifraud Portal – Automatic checking of shipped and shipped products |

| TEC7 |  | RFID Portal Automatic Receipt and Handling of Road Products | RFID Portal – Collection of product information in road transport updating intercompany stock automatically. |

AMS – ArcelorMittal Sistemas was the company responsible for the development and coordination of the entire project. It was supported by the selected companies:

– PCX Tecnologia – provide and support the approval of RFID equipment;

– Automaway – implement automation project requirements and solutions (portals, collectors, forklifts, overhead cranes), Middleware application and MES interfaces;

– Itapem – Engineering projects and technical documentation of all solutions (Word and CAD).

PCX Tecnologia Companies and Automaway are participants in the IMPINJ Channels program.

With this multidisciplinary team, the results can be seen in the table below:

| Project | Adopted Products | Innovations | Results |

| Industry 4.0: TEC1 |  | Automation of Industrial processes, equipment and devices. Industry 4.0 | Cost reduction, productivity, assertiveness, safety and competitiveness. Application of RAIN RFID tags and tags |

| RFID Portal: TEC2 |  | RFID Portal with Speedway R420 Impinj Readers. Industrial process automation in automatic collection | Reception of products in the 100% automated logistics stock. Factory floor FTE withdrawal. Assertiveness of logistical stocks. Update of constant stocks and in real time. Safety, productivity and automatic product traceability. Application of the fixed reader RAIN RFID Speedway R420 Impinj. |

| RFID Mobile Collector: TEC3 |  | RFID mobile collector for contingency in QRCode / Barcode options and RFID manual operations. | Productivity and automatic product traceability. Application of the RAIN RFID mobile collector operating SAP with the functions of moving, auditing, receiving, consulting and dispatching laminate production |

| RFID Overhead Cranes: TEC4 |  | Moving Rolled Products automatically updating inventories and dispatching products via overhead cranes with RAIN RFID Speedway R420 Impinj readers. | Productivity and agility in logistics operations. TPV reduction by 50%. Stock reliability and security by eliminating operator traffic on the shop floor. Rolling Bridges – Integrated automation solution operating in the movement and dispatch of products. Application of the fixed reader RAIN RFID Reader Speedway R420 Impinj with integrations by external GPIO. Initial solution with R420 and in 2022 being expanded and updated to other units with R700 Impinj readers. |

| RFID Forklifts: TEC5 |  | Moving rolled products automatically updating inventories and shipping products via forklifts with RAIN RFID Speedway R420 Impinj readers. | Productivity and agility in logistics operations. TPV reduction by 50%. Stock reliability and security by eliminating operator traffic on the shop floor. Quality. Operators work in climate-controlled cabins. Forklifts – Integrated automation solution operating in the movement and dispatch of products. Application of RAIN RFID Speedway R420 Impinj fixed reader with external GPIO integrations. Initial solution with R420 and in 2022 being expanded and updated to other units with R700 Impinj readers. |

| Anti-Fraud Portal: TEC6 |  | Automatic anti-fraud solution with RAIN RFID portal readers RAIN RFID Speedway R420 Impinj. | Safety in the process and end of deviations due to fraud – Automatic checking of products shipped according to shipment order. |

| Portal RFID Recebimento: TEC7 |  | Receipt of Inputs (laminated products) automatically through an RFID portal to automatic receipt of road products | Reception of products in stock 100% automatic. Factory floor FTE withdrawal. Reliability of logistical stock. Safety and Productivity. Collection and receipt of rolled products in road transport via RFID portal. Updating of logistics stock automatically, with intercompany transfers. |

|  |

The choice and use of world-class products and industrial robustness was crucial to the success of the Project. IMPINJ products were exclusive for RFID solutions and products from other companies for other requirements. According to Terror, these are Projects to serve the Industry with solutions to operate in a strategic, critical mission, in a hostile environment that requires high availability.

IMPINJ was the main partner in the project, supporting the channels through its product engineering team.

The Intelligent Logistics project: ArcelorMittal Brasil Longos continues to grow. In addition to the expansions planned for 2022 in new business units with the technological update with the Impinj R700 reader, new challenges are being proposed. The objective is to always use the application of the Industry 4.0 concept with RAIN RFID.