RFID solution with Impinj technology aims to eliminate failures in the marking and identification of harvested bales, which guarantees more quality and better price

30 de July de 2020

By Edson Perin

ID-Cotton developed a radiofrequency identification (RFID) solution three years ago for the traceability of cotton, from the harvest to its processing. Flávio Tarasoff, executive director of ID-Cotton, says that it is a product aimed at the annual harvest. “We started with a production unit and today we already have more than 45 using the solutions”.

Bom Futuro Agro Group, largest Brazilian cotton producer, it was a pioneer in the use of ID-Cotton. Then come the units of the Scheffer, Amaggi, Locks and Cortezia Agro Groups, all from Mato Grosso, which together represent more than 20% of the Brazilian feather production. “For the Brazilian harvest, Conab estimates that the area with cotton should reach 1.7 million hectares in 2020, while production should be relatively stable at 2.82 million tons”, he informs.

Headquartered in Cuiabá (MT), ID-Cotton centralizes in its headquarters office the production, operation, support and sales of the systems. “In addition, this year we established ID-Cotton Agribusiness LLC, in the United States, based in the city of Doral, Florida,” says Tarasoff. “The location is strategic, because it is close to the local port and airport, and will concentrate the manufacture of equipment to distribute on the international market, with the kits already ready. The proximity to Texas is also a facilitator, because there is the largest cotton acreage in the USA ”.

Tarasoff spoke exclusively with Edson Perin, editor of the IoP Journal, about this project. Find out more by watching the interview below (vídeo in Portuguese):

ID-Cotton’s solutions for cotton traceability aim to combat flaws in the marking and identification processes of harvested bales. In addition, they eliminate manual labels, handwritten spreadsheets, “spray painting on canvas and other ancient methods of identifying producer, farm, variety, field, border and contaminants.

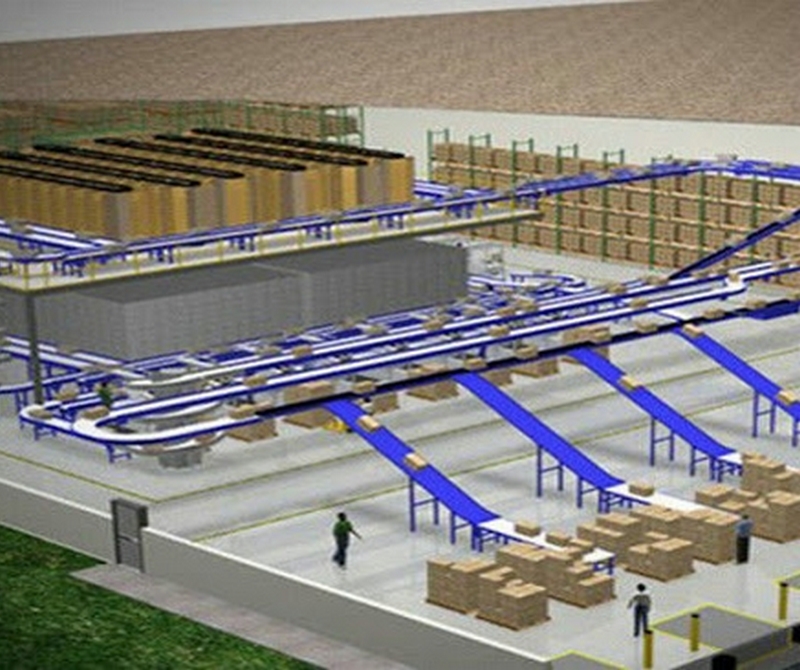

The ID-Cotton system facilitates yard management and processing, avoiding contamination of cotton varieties, ensuring the final quality of the product and also the price of the feather cotton sign.

The Impinj partner community represents a wide range of services, geographies, solutions and domain knowledge complementary with a common theme: the search for the best RFID solutions in the category. According to Gaylene Meyer, vice president of marketing and global communication at Impinj, the company continues to build relationships with partners who can best meet the needs of agribusiness for asset tracking, livestock management, supply chain traceability and more.

“We are pleased that ID-Cotton has chosen the Impinj platform for this important agricultural industry project,” says Gaylene. “Its successful deployment is an example of how the Impinj platform allows our partners to connect items to the Internet of Things, improving visibility and increasing efficiency “.

All management before the ID-Cotton RFID system was carried out in the cotton sector through labels and manual processes, such as bar codes. The RFID implantation follows the passive EPC UHF standard, from GS1. “The main benefit is the traceability of production, operational management, storage and increased gain in the classification of the feather, when using all ID-Cotton tools”, he guarantees. The tags in use are equipped with Impinj’s Monza5 and Monza 6 chips, from the moment of harvest until the bales are processed.

“This year we are importing the data that was recorded on the canvas tags for the new RFID tags, which will be added to the cotton lint, which can be used for packaging management, screening of laboratory analyzes, cargo management, loading and unloading and classification plume in the next production chain, which are the spinning mills ”.

In practice, after the cotton harvest, the RFID tags – inserted in the cotton rolls – are read and recognized by means of a tablet with the ID-Cotton system. This information is synchronized with the company’s ERP, which in a second moment automatically reads the loads of these rolls through an RFID portal when transferring the cotton crop, dropping the cotton from the crop and transferring this stock into the processing unit.

“One of the most important factors”, explains Tarasoff, “was the technological change, because before in the harvesting and transportation of cotton, barcode labels were used, which presented several flaws, from lack of reading to registration errors, since the process was done manually ”. The solution developed by ID-Cotton offers integration with management systems (ERP). “By facilitating the marking and identification of bales in the field, the ID-Cotton system has an impact on increasing productivity and reduces the team in the field”.

With the bales receiving a unique identification, transport management becomes more agile, as well as the real-time location of each package. “Our technology reduces the time in the yard and the use of the scale,” he says. “Finally, the system saves on personnel, labels and manual processes, guaranteeing real gains in the final value of cotton”. Because it is modular, ID-Cotton serves the major players in agribusiness and can also be used by farmers, cotton units, cooperatives, among others.

The RFID technology from Impinj, a manufacturer of reading equipment and radio frequency identification chips, was chosen by ID-Cotton to be added to the platform developed by the Brazilian company. “We used the equipment in the Speedway Impinj line, with changes in the controller’s firmware and an operating rule developed together with the ID-Cotton team and the Impinj engineering,” reports Tarasoff.

The Impinj platform used throughout the cotton tracking solution contains Impinj Monza chips and tags attached to cotton rolls, Impinj Indy chips with RFID functionality for handheld readers and equipment used in the field and on farms and processing centers for read the rolls. Impinj Speedway readers are used in portals and elsewhere to read the rollers.

The ID-Cotton and Impinj partnership is ready to compete in the international cotton market. Impinj products operate globally and can be used by ID-Cotton as they expand their solution offering. Australian cotton gin operator Southern Cotton had previously announced the use of Impinj products in this sector.

The RFID readings were related to the mass, density, structure of the vehicles that handle the cargo, climatic conditions, rain, serene, humidity, position of the bale in the trailer, variety of trailers with different heights and volumes, angles of attack of the scales and flaws in other manufacturers’ processes. “As it is a completely new technology, there were many challenges, most of which were focused on transportation”, attests Tarasoff.

The differences in tare weight of the truck without the load and the structure of the vehicles, as well as the variety of trailers with different heights and volumes and the position of the cotton bales, were questions analyzed to carry out the readings without fail. “Climatic conditions”, says Tarasoff, “how rain, sun, serene and relative humidity also influence and the system needed to take these variants into account”. To carry out the weighing at the stations, it was necessary to check all the angles of attack of the scales on the roads so that there were no reading errors.

According to Alexandre Carvalho, information technology manager at Bom Futuro Group, the advantages of using ID-COTTON have been many, starting with the gain in reliability in cotton traceability. “Technology has also promoted more agility in the field and in transportation with automation in weighing trucks. All of this generated greater quality of information for decision making ”, he explains. “Now, we intend to expand RFID into the production process, ensuring quality and shipment of cotton bales”.

Another gain was the integration of data collection from John Deere harvesters, within the ERP, as well as all integration of this information with the ID-Cotton System, in a cloud database. “The high productivity in the field, thanks to the agility in data collection, data reliability, more information for coordinated analysis with GPS, humidity, harvester, driver, etc., certainly met expectations”, says the executive.